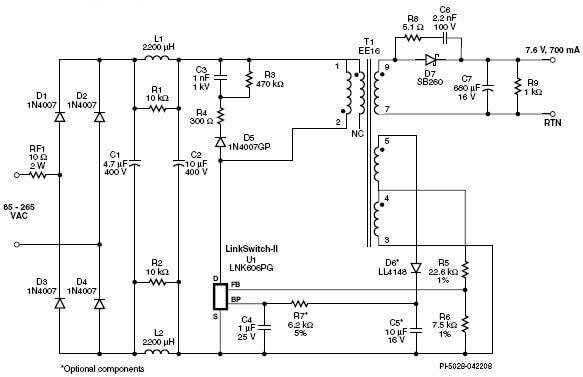

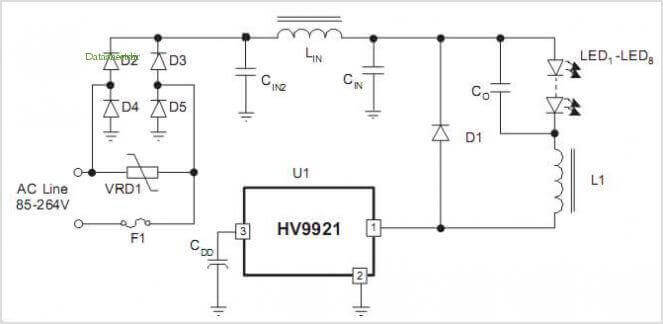

Currently in the general LED lighting market, there is a non-isolated and isolated difference for driver powers. Non-isolated design is limited to double insulation products, such as light bulbs alternative products, including LED and the product are integrated and sealed in a non-conductive plastic, so the end user does not have any risk of electric shock. Products of Class II are isolated, the price is relatively expensive, but the user can access to the LED and output wiring place (usually applied in LED lighting and street lighting), this product is essential.

With isolation transformer or electrical isolation LED driver power supply means that the LED can be directly touched by hand without electric shock. Without isolation transformer, though it still can make use of protective shell to achieve some mechanical insulation, but this time the LED can not be in direct contact with when at work.

Insulation bulb will play a main role in the future

Physical design determines the driver is isolated or non-isolated. Safety rules often require two independent isolation layer. Designers can choose two physical barrier, such as plastic diffuse and glass cover with non-isolated power. If the physical isolation cost is too much, mechanical difficulties, or absorb too much light, it is necessary to solve the problem of electrical isolation in the power supply.

Based on same power, isolated power supply is usually larger than the non-isolated power. Lighting designer must do lots of cost and design optimization work when they design each product. Because for different applications, whether using insulated transformer isolation or using protective shell lampshade isolation, different designers always have different opinions.

Based on same power, isolated power supply is usually larger than the non-isolated power. Lighting designer must do lots of cost and design optimization work when they design each product. Because for different applications, whether using insulated transformer isolation or using protective shell lampshade isolation, different designers always have different opinions.

Typically, they will analyze from various aspects, such as cost and manufacturing processes, efficiency and volume, insulation reliability and safety regulations, and so on. Driver with a transformer cost more, but it can make corresponding LED lamps become more practical, able to meet the needs of end-users incidental contact with the LED. When the incandescent lamp glass casing can easily be damaged, a common type E27 bulb can be replaced become the LED lights.

Further, in the industrial area or office equipment applications, lamps do not need access to end-users, such as shopping malls and street lighting, at this time the LED lights do need isolation transformer.

As for making sure safety for the end-user, we will consider the reliability of insulation and isolation. As a complete product, the surface portion which will be accessed to must go through quarantine so that people will not get an electric shock. From the whole system, isolation is inevitable, in fact just the isolation position difference. Some designers use isolation transformer design, so heat dissipation and lampshade  design can be simplified. If the driving design non-isolated, then the lamp housing and other structures must be considered reliable insulation requirements. Therefore, as a power drive, isolated and non-isolated solutions always exist at the same time.

design can be simplified. If the driving design non-isolated, then the lamp housing and other structures must be considered reliable insulation requirements. Therefore, as a power drive, isolated and non-isolated solutions always exist at the same time.

The main challenge China LED driver power supply manufacturers may face is to find a low cost AC / DC drives to meet more stringent achieve power factor and efficiency in the low-cost power system performance.

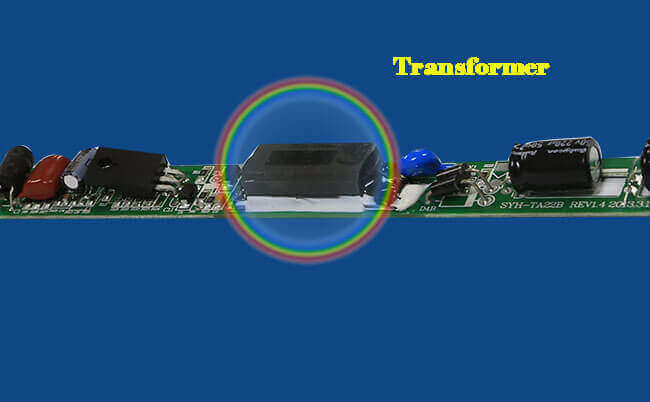

LED driver power with transformer-based isolation will be the mainstream

Isolated and non-isolated LED driver power supply options have their advantages and disadvantages. The insiders believes that, Class II will be the mainstream, because it simplifies the LED heat problem. Class I or II system relies grounding system, in most cases, is closely related with the installation site. Class II is more common, which requires a two-stage or enhanced isolation, that require magnetic transformer windings, insulation tape, and physical isolation. Class I system requires a grounded enclosure and (or) mechanical barrier, but this time Class II system is unnecessary.

Isolated and non-isolated LED driver power supply options have their advantages and disadvantages. The insiders believes that, Class II will be the mainstream, because it simplifies the LED heat problem. Class I or II system relies grounding system, in most cases, is closely related with the installation site. Class II is more common, which requires a two-stage or enhanced isolation, that require magnetic transformer windings, insulation tape, and physical isolation. Class I system requires a grounded enclosure and (or) mechanical barrier, but this time Class II system is unnecessary.

There are several trends are driving the development of LED lighting market. First, contentious improvement for high-brightness LED efficiency, and contentious turning up of high efficiency high reliability constant current LED driver power supply. Secondly, global legislation to ban incandescent lighting (due to their low efficiency) and the phasing out of the CFL energy-saving lamps (if it break then it will be out of environmentally harmful mercury). These factors combine to make LED lighting has become a positive long-term trends. Of course, low system cost (including LED, LED thermal management systems and drive) is always the driving force to widely used in consumer LED general lighting.